In the fast-paced automotive industry, the demand for high-quality, precision-engineered component parts is greater than ever. Whether it’s for engine components, suspension systems, or braking mechanisms, every part needs to meet strict quality and durability standards. One of the most effective manufacturing methods to achieve this level of precision is CNC machining.

At KEVORAPID, we specialize in CNC machining services tailored for the automotive industry. Our advanced CNC technology allows us to produce complex, high-performance parts that meet the specific needs of our clients. In this blog, we will explore the critical auto components that benefit from CNC machining and why this manufacturing process is ideal for creating the parts your business requires.

Why Choose CNC Machining for Automotive Component Parts?

CNC machining offers several advantages that make it the preferred choice for manufacturing automotive components:

- Unmatched Precision: CNC machines can achieve tight tolerances and intricate details that are essential for automotive parts.

- High Efficiency: Ideal for both prototyping and large-scale production, ensuring faster lead times.

- Material Versatility: Compatible with a wide range of materials, including aluminum, stainless steel, titanium, and engineered plastics.

- Consistency: Ensures uniform quality across all parts, critical for safety and performance in the automotive industry.

If you’re looking for a reliable partner to produce your custom auto parts, our CNC machining services are designed to meet your exact needs. Let’s dive into the key components that we can help you manufacture.

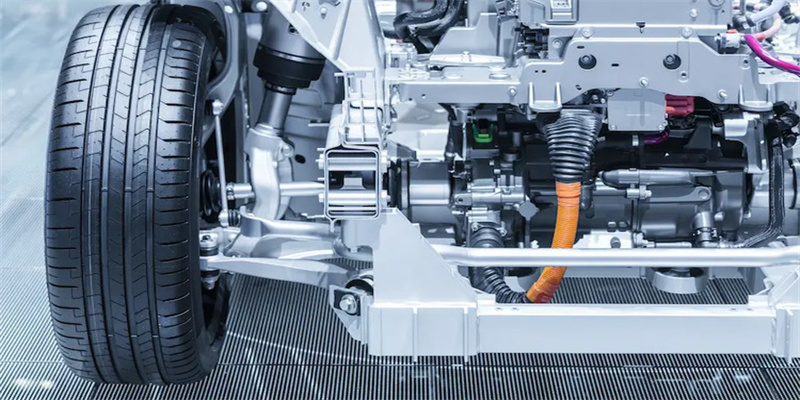

1. Engine Components: Precision for Optimal Performance

The engine is the heart of any vehicle, and its components must be manufactured with the utmost precision. CNC machining is perfect for creating high-quality engine parts, including:

Key Engine Components We Manufacture

- Cylinder Heads: CNC machining ensures the precise shaping of cylinder heads, which is essential for efficient airflow and optimal combustion.

- Pistons: Custom pistons require exact dimensions for seamless movement and to withstand high temperatures.

- Crankshafts: CNC machining produces crankshafts with intricate designs and tight tolerances, enhancing engine performance.

- Camshafts: These parts need accurate profiles to control valve timing effectively, ensuring optimal engine function.

Need custom engine components? Send us your specifications, and our team will provide you with a tailored solution.

2. Transmission Parts: Durable and Accurate Solutions

The transmission system is responsible for transferring power from the engine to the wheels. It requires parts that are not only precise but also durable enough to handle intense mechanical stress. CNC machining delivers the consistency and accuracy needed for these critical components.

Transmission Parts We Specialize In

- Gears: High-precision CNC machining ensures the smooth operation of gears, reducing wear and extending the life of the transmission.

- Shafts: Custom shafts manufactured with tight tolerances provide superior strength and performance.

- Housings: Complex transmission housings can be precisely machined to fit seamlessly with other components.

Looking to improve your transmission components? Contact us for a custom quote and learn how our CNC machining services can help.

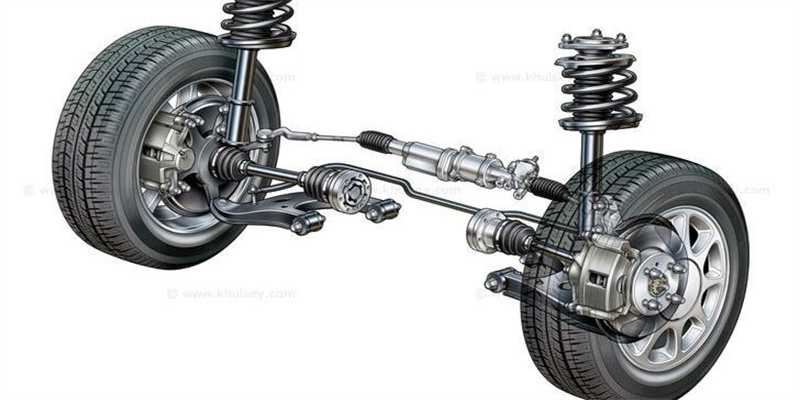

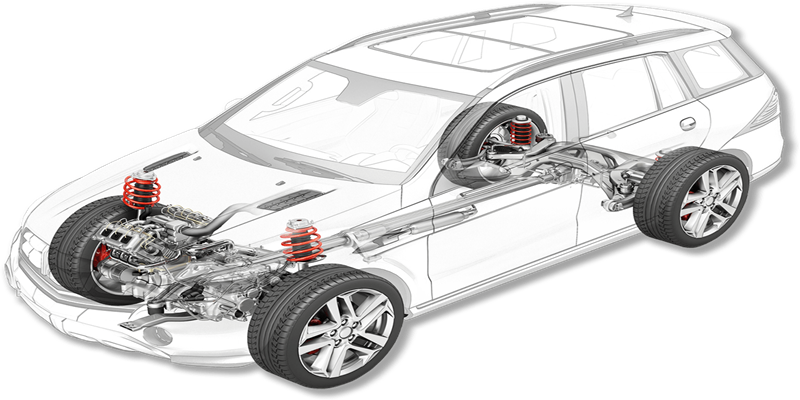

3.Suspension Components: Strength and Reliability

The suspension system plays a crucial role in a vehicle’s stability and comfort. CNC machining allows for the creation of robust and precise suspension components that enhance handling and ride quality.

Common CNC Machined Suspension Parts

- Control Arms: Machined for maximum strength, control arms provide better handling and reduced vibration.

- Shock Mounts: Custom CNC-machined mounts ensure a secure fit and long-lasting durability.

- Steering Knuckles: These parts are machined to exact specifications for accurate steering response.

Upgrade your suspension components with our high-precision CNC machining services. Send us your designs or specifications to get started.

4.Brake System Parts: Safety and Precision

When it comes to vehicle safety, the brake system is paramount. CNC machining is used extensively to manufacture high-performance brake components that require precise engineering and high strength.

Key Brake Components We Manufacture

- Brake Calipers: CNC machining creates calipers that offer a perfect fit and optimal braking force.

- Rotors: Precision-machined rotors provide consistent braking performance and minimize wear.

- Brake Pistons: These components must be flawlessly manufactured to ensure effective braking pressure.

Ensure your vehicles have the best braking performance. Contact us to learn more about our CNC machining capabilities for brake components.

5.Custom Interior and Exterior Parts: Enhance Vehicle Design

In addition to functional components, CNC machining can produce a variety of custom interior and exterior parts, enhancing the look and feel of a vehicle.

Examples of Custom Parts

- Dashboards and Trim: Create sleek, custom designs for a unique interior appearance.

- Grilles and Emblems: Precision machining allows for detailed, high-quality finishes.

- Custom Brackets and Mounts: Tailored parts to fit your specific requirements, offering strength and reliability.

Looking for a custom touch? Send us your design ideas, and we’ll help you bring them to life with precision and style.

Why Choose Us for Your CNC Machining Needs?

At KEVORAPID, we understand the importance of quality and reliability in the automotive industry. Here’s why you should partner with us:

- State-of-the-Art Equipment: We use the latest CNC machines to ensure top-notch precision and efficiency.

- Experienced Team: Our engineers and machinists have years of experience in the automotive sector, delivering expert craftsmanship.

- Comprehensive Services: From design support to production and quality assurance, we handle every step of the process.

- Fast Turnaround: We prioritize efficiency to meet your deadlines without compromising on quality.

Get a Custom Quote Today

Ready to take your automotive project to the next level? We offer free consultations and custom quotes tailored to your specific needs. Simply visit our website and fill out our inquiry form, or contact our team directly for more information.

Conclusion

The automotive industry demands high-quality, precision-engineered components, and CNC machining is the perfect solution to meet these needs. From engine parts to custom interior pieces, our services provide the accuracy, durability, and customization you require. Don’t settle for off-the-shelf solutions—partner with us for bespoke manufacturing that meets your exact specifications.

Ready to Get Started? Visit our website or contact us today to request a quote and discover how we can help you manufacture the best automotive components for your business.

By highlighting the capabilities of CNC machining in producing critical automotive components, this blog is designed to attract potential customers to your website and encourage them to send inquiries. Let me know if there are additional details you’d like to include!