Medical Device Prototyping And Manufacturing

As the cornerstone of your medical product design and development process, our expertise lies in medical device prototyping and rapid manufacturing. By entrusting us with your prototype parts and low-volume production, you can expedite the process of sending them to the lab, clinical trials, and ultimately to market.

Rapid Manufacturing In Medical Device Development

In the realm of medical device design and development, costs and time constraints can pose challenges. However, exceptional innovators redefine industry standards, enabling the efficient and cost-effective journey of new medical devices to the market.

A rapid prototyping manufacturer specializes in delivering functional prototypes and low-volume production parts for medical devices and health products. This facilitates concept and market testing, allowing you to gather early customer feedback, explore ideas, and develop purposeful solutions. By leveraging this process, you can swiftly advance to lab or clinical trials, ultimately expediting the route to market. Additionally, it provides valuable insights into subsequent manufacturing processes, costs, schedules, and quality control.

What Materials Work Best for Medical Applications?

High-temp Plastics. PEEK and PEI (Ultem) offer high-temperature resistance, creep resistance, and are suited for applications that require sterilization.

Medical-grade Silicone Rubber. Dow Corning’s QP1-250 has excellent thermal, chemical, and electrical resistance. It’s also bio-compatible so can be used in applications that require skin contact.

Carbon RPU and FPU. Carbon DLS uses rigid and semi-rigid polyurethane materials to build functional parts ideal for late-stage prototyping or end-use devices.

Micro-resolution. MicroFine™ (green and gray) is a proprietary material developed by Protolabs to build complex 3D-printed parts with micro-sized features as small as 0.0025 in.

Microfluidics. Watershed (ABS-like) and Accura 60 (PC-like) are clear materials can be used for microfluidic parts and transparent components like lenses and housings.

Medical Alloys. Between machined and 3D-printed metals along with sheet metal, there are more than 20 metal material options available for medical components, instrumentation, and other applications. Metals like titanium and Inconel have attributes like temperature resistance while various stainless steel materials brings corrosion resistance and strength.

Best Practices Supported By Medical Device Prototyping And Manufacturing

With expertise in my field, I excel at shaping product ideas for medical devices into manageable scopes. By creating proof-of-concept prototypes, I ensure a thorough understanding of the design intent and establish critical details.

In my role as a product development expert, I focus on refining product ideas for medical devices and bringing them into a manageable scope. Through the use of proof-of-concept prototypes, I work diligently to establish critical details and gain a comprehensive understanding of the design intent.

As an expert in medical device prototype development, I specialize in creating functional prototypes (also known as Beta prototypes). These prototypes serve as a valuable tool for testing the form, fit, and function of parts, allowing for design refinements and improved product performance. By identifying and addressing any issues early on, these prototypes significantly reduce business risk before reaching the final product stage.

As a medical device prototyping specialist, I specialize in creating engineering prototypes that closely resemble the final product. This allows for efficient verification of design, engineering, and manufacturability, saving costs by identifying any potential issues before investing in expensive tools and initiating production.

In my profession as a rapid manufacturing and low-volume production expert, I facilitate a seamless transition from medical device prototypes to market-ready products. Through cost-effective manufacturing methods, I ensure speedy product launch while maintaining affordability.

Dedicated To The Development And Manufacture Of Medical Devices

WayKen offers a full range of rapid prototyping and manufacturing solutions to the medical industry. From surgical tools to large-scale treatment units, our engineering approach will help you move from your initial idea to a realistic plan.

Medical Device Prototyping And Medical Parts On-Demand Manufacturing

With extensive expertise, Kevorapid is a leading provider of medical device prototyping and machining services. Our global clientele of medical device manufacturers can attest to our commitment to excellence. From initial prototypes to testing, iterations, and product demonstrations, we guide you through every step of the process. Additionally, our comprehensive prototyping and manufacturing capabilities, including CNC machining, 3D printing, urethane casting, and rapid injection molding, ensure that we meet all your medical device development requirements.

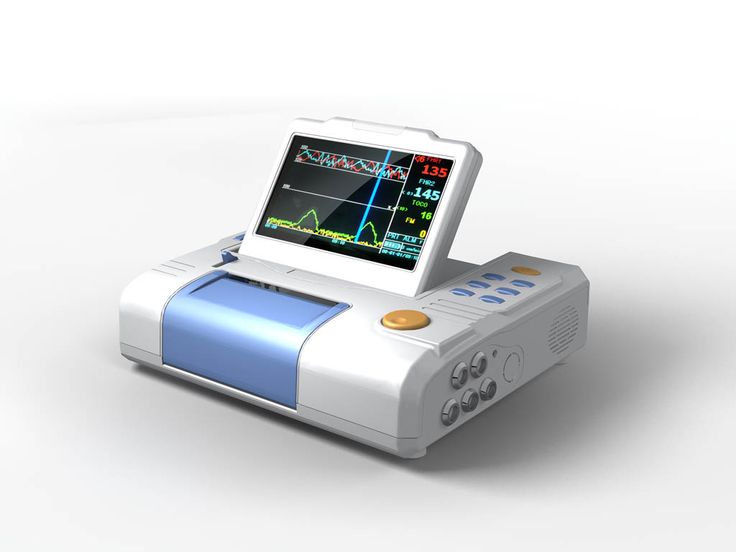

Medical Device Enclosures, Custom Machined Plastic Housings

Surgical Instruments And Surgical Tools, Precision CNC Machining For Medical Components

In high-precision manufacturing, CNC machining reigns supreme, particularly in professions demanding accuracy and adherence to safety standards, like the production of surgical instruments and tools. At WayKen, we excel in machining medical-grade materials, including titanium and stainless steel, with utmost efficiency and precision. Our expertise lies in the precise machining of intricate geometric details, employing advanced techniques such as 5-axis micro-milling. By leveraging a combination of manufacturing processes, such as metal injection molding, metal casting, EDM, and wire EDM, we deliver the most optimal precision machining solutions. Our medical machining capabilities boast dimensional tolerances of ±0.01mm, geometric tolerances of 0.01mm, a minimum machined radius of R0.1mm, and a machined surface roughness of Ra0.2μm.

Dedicated To The Development And Manufacture Of Medical Devices

KevoRapid specializes in offering end-to-end rapid prototyping and manufacturing solutions specifically designed for the medical industry. From surgical tools to large-scale treatment units, our engineering approach streamlines the journey from concept to a feasible plan.