Automotive Prototyping And Parts

Manufacturing

Experience our comprehensive automotive prototyping and parts manufacturing services. From proof of concept design to mechanical component engineering tests, and from exterior lighting prototypes to interior part manufacturing, we provide complete support at every level. Our expertise in this field allows us to continuously expand our knowledge and experience, ensuring top-notch service.

As the automotive industry rapidly evolves, Protolabs is the go-to solution for agile-minded companies. With cutting-edge technology and automated feedback, we enable automotive companies to accelerate product development and reach the market with unprecedented speed. Our quick-turn digital manufacturing and responsive supply chain help designers and engineers mitigate design and cost risks while meeting the growing demand for customized vehicles driven by trends like autonomous driving, on-board connectivity, and hybrid/electric vehicles.

What Materials Work Best for Automotive Applications?

Thermoplastics. Choose from hundreds of thermo plastics including PEEK, acetal, or supply your own material. Maintain branding with custom colorant for qualified projects.

Liquid Silicone Rubber. Silicone rubber materials such as fuel-resistant fluorosilicone can be used for gaskets, seals, and tubing. An optical clarity silicone rubber is also available for lens and lighting applications.

Nylons. 3D print functional prototypes in several nylon materials available through selective laser sintering and Multi Jet Fusion. Mineral- and glass-filled nylons improve mechanical properties when needed.

Aluminum. This all-purpose metal used for light-weighting provides excellent strength-to-weight ratio and can be machined or 3D printed.

KevoRapid's Automotive Prototyping And Parts Manufacturing Technology Plays A Role At Every Point In Your Process

We excel in various manufacturing techniques to bring your designs to life quickly. We will work together – and with you – throughout every step of the automotive design and development process.

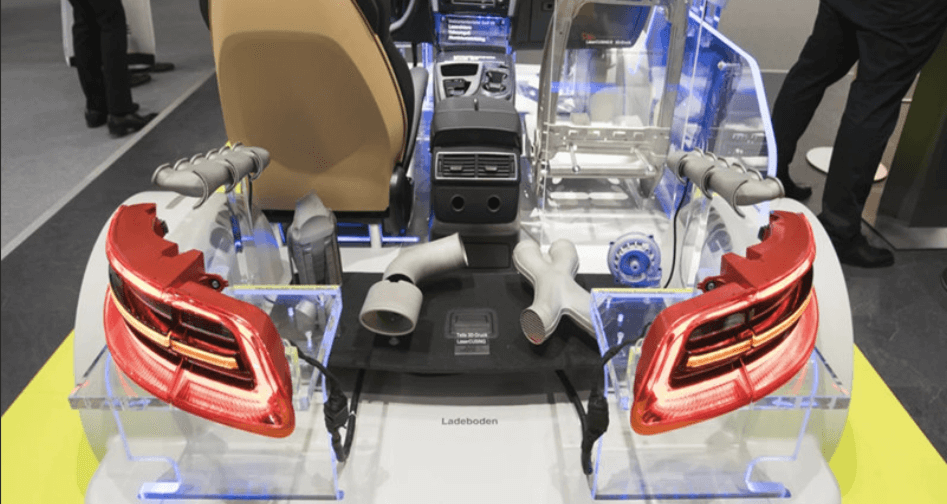

Automotive Lighting Lamps – Optical Component Prototypes

Auto Lamp Lens – Machining Acrylic and Clear Polishing

- Expertise in machining and polishing acrylic for auto lamp lenses Unrivaled skills in handling thin-walled clear plastic materials Cutting-edge technology for hand finishing and polishing Specialization in advanced two-color and multi-material (2K) molding process

Light Guides and Aluminium Reflectors – Precision Optical Machining

- Combine 5-axis precision milling and diamond machining for superior results Attain complex geometric shapes and precise optical details with ease Maintain tight tolerances with a minimum machining radius of R0.1mm and surface tolerance of ±0.02mm Achieve smooth surfaces with CNC milled roughness of Ra(μm) 0.2 and mirror-polished roughness of Ra(μm) 0.05

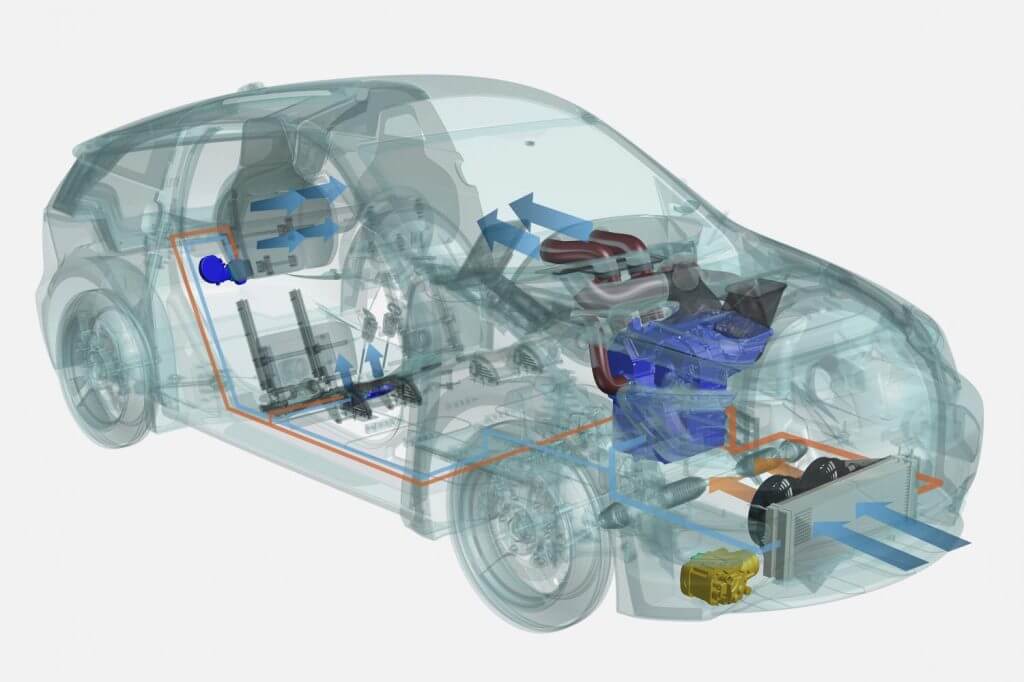

Automotive Mechanical Components – Functional Prototypes

Kevo specializes in functional prototyping for automotive mechanical components. Our expertise lies in CNC machining, silicone molding, and rapid tooling processes. This allows us to provide accurate performance feedback and data through rigorous testing, refining your designs effectively. We use the same materials as the final parts to realistically simulate mechanical function, electric performance, and thermal properties. Our capabilities include creating complex, workable components to ensure proper form and fit within assemblies. With precision machined prototypes, we can accurately measure, compare, and identify design errors, dimensional differences, and acceptable tolerances.

Custom Auto Parts – Low-Volume Manufacturing

- Custom Low Volume CNC Machining

With state-of-the-art machining equipment and adaptable production methods, Kevo is equipped to handle a wide range of projects. Our capabilities span from simple milling and turning to complex and precise 5-axis CNC machining. Additionally, we excel in both production-grade plastic and precision metal machining, offering a diverse array of advantages. - Cost-effective Rapid Injection Molding

Benefit from our years of expertise in rapid mold production for aluminum, steel, and plastic injection molding. We understand the importance of meeting your engineering testing and pre-production schedule, and are committed to delivering parts promptly to support your project