Clear Optical Prototypes

Our primary objective is to develop prototypes of transparent components, and we possess the necessary skills in precision machining and rapid tooling for creating customized optical prototypes.

Clear Optical Prototypes Services

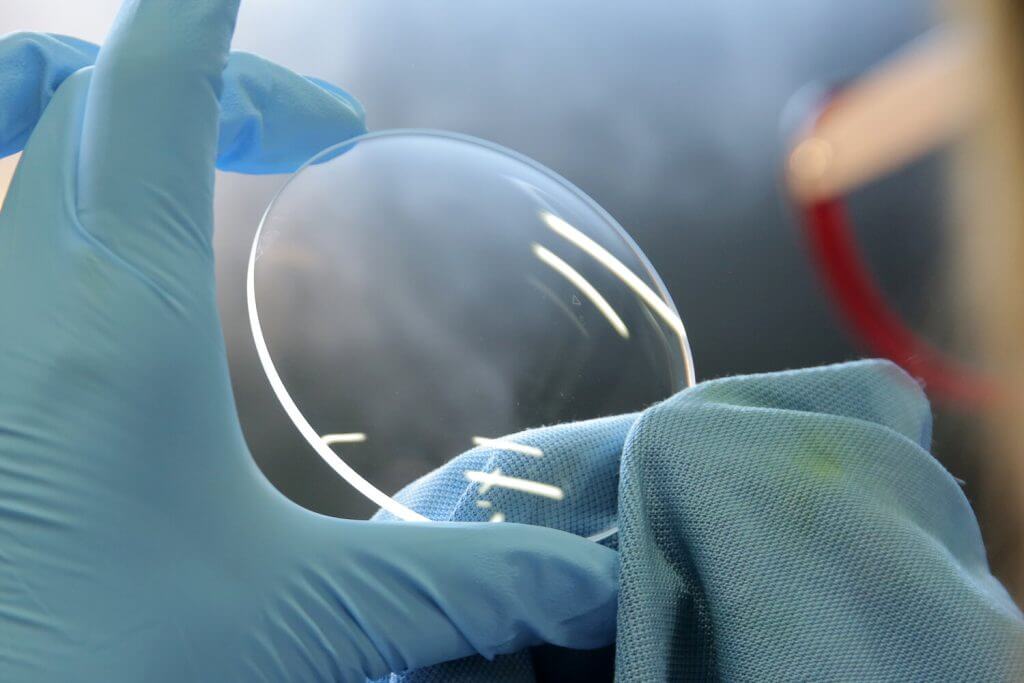

Enhance your prototyping applications with clear plastic parts, perfect for optical functions, product visibility, and aesthetics. Our clear prototypes and optical prototypes machining excel in crafting transparent acrylic (PMMA) and polycarbonate (PC), delivering a stunning mirror-clear effect. From automotive lighting lamp lenses to light guides and product external components. Kevo offers custom solutions tailored to your needs.Experience our expertise in CNC machining, vacuum casting, and injection molding to create flawless clear parts. With highly skilled polishing techniques, we achieve unmatched optical clarity on plastic components. Count on us for comprehensive support throughout your optical prototype development projects, ensuring excellence at every step.

Optical Prototypes With Precision CNC Machining

Machining Acrylic & Hand Polishing

- Embrace the brilliance of CNC machined clear plastic using acrylic (PMMA) – the ultimate choice for impeccable surface finish. Our precision machining and acrylic polishing techniques guarantee unmatched clarity and light transmittance. As a distinguished prototype manufacturer, we take great pride in our advanced excellence, crafting flawless acrylic prototypes for optical components. Join us on a journey of innovation and experience the highest level of clarity and quality in your prototypes.

Machining PC & Vapor Polishing

- Polycarbonate (PC) emerges as a top contender for CNC machining among transparent plastics. Its impressive transparency rivals acrylic, while its exceptional strength sets it apart. Elevate your PC parts with our cutting-edge vapor polishing for impeccable post-finishing. At Kevo, we take pride in offering a seamless combination of transparency and strength through our advanced CNC machining and expert vapor polishing techniques. Discover the true potential of your prototypes with us.

Short Runs Casting Clear Prototypes

Unlock the potential of urethane vacuum casting for swift and cost-effective creation of transparent plastic prototypes in small quantities. At WayKen, we excel in producing optically clear parts, starting with CNC machined and highly polished acrylic masters for impeccable surface finish. Our precision machined masters ensure the finest optical pattern details, while the right casting process and carefully selected silicone and polyurethane materials guarantee exceptional results.

We take great care in choosing and applying release agents to avoid tackiness and surface defects. Utilizing the overmolding process, we achieve single urethane parts with two-color or two-component properties. Typically, 12-15 clear copies, or even up to 20 copies per mold (depending on complexity), can be produced. When needed, we can deliver more than 20 clear parts in just two weeks or less, depending on the structure and volume.

With KEVO’s expertise, your prototypes will come to life with precision and speed, making your vision a reality in no time.

Injection Molded Clear Parts For Low Volume

Rapid injection molding enables the utilization of anticipated production materials and final production technology for clear plastic components. It is possible to attain Class A surface finishes when manufacturing injection molded optical components and transparent parts using materials such as PMMA and PC.

Whether you require as few as 100 or more than 10,000 clear plastic parts for testing low volume production runs, we possess the expertise and experience in creating rapid aluminum tooling. This results in reduced tooling expenses and expedited production changeovers.

Applications For Prototyping Clear Parts

Clear Optical Prototyping Application of Auto Parts

KevoRapid is dedicated to delivering top-notch automotive lighting prototypes, offering a complete range of services. Our deep-rooted expertise in this domain has empowered us to elevate our knowledge and experience. We provide comprehensive support at all levels, from meticulous mechanical component design reviews to groundbreaking optical development engineering tests. Our proficiency also extends to flawlessly executing show car projects with unrivaled precision.

Clear Prototypes – Auto Housing

- Machining experience of thin-walled clear plastic

- Unparalleled hand finishing and polishing technology

- Advanced two-color and multi-material (2K) molding process

Optical Prototypes – Auto Light

- Combine 5-axis precision milling with diamond machining technology

- More complex geometric shapes and precise optical details can be achieved

- Minimum machining radius

Clear Optical Prototyping Application of Pet Accessories

KevoRapid is dedicated to Premium Acrylic Material ,pet products is made of high quality acrylic, with the look of glass and the durability of steel, totally non-toxic and safe for your puppy, transparent appearance providing clear visibility and blending perfectly into your home.

Clear Prototypes – Acrylic Dog Cat Bowls

- Stylish and sturdy.It’s rust-free and won’t deform over time

- Our elevated feeder set comes with everything your pet needs

- Removable bowls make it easy to replace and clean

Optical Prototypes – Acrylic Indoor Dog House

- Aesthetic dog crate ventilated side windows increased air circulation

- Premium acrylic material transparent appearance providing visibility

- Easy to asssemble provide installation instruction in each package

Clear Optical Prototyping Application of Cosmetic Products

KevoRapid is dedicated to Premium Acrylic Material ,pet products is made of high quality acrylic, with the look of glass and the durability of steel, totally non-toxic and safe for your puppy, transparent appearance providing clear visibility and blending perfectly into your home.

Clear Prototypes – Jewelry Organizer

- Acrylic Jewelry Case Transparent Cosmetic Display Box

- Keep cosmetics Jewelry organized. Great for makeup brushes

- Drawers can be used side-by-side or stacked to save counter space

Optical Prototypes – Acrylic Indoor Dog House

- Offers ample space to neatly store and display your cosmetics

- Transparent easily find your favorite beauty products visibility

- Multifunctional compartments ample space to organize products