Keeping your electronics cool isn’t just about comfort; it’s about performance, longevity, and reliability. At the heart of many thermal management solutions sits the humble heat sink. But with materials like copper and aluminum dominating the market, which is right for your project? And why are so many turning to China for their heat sink needs? Let’s dive in.

1. How Does a Heat Sink Work? The Simple Physics of Cooling

Think of a heat sink as a radiator for your electronic components (like CPUs, GPUs, or power transistors). Its job is heat transfer:

-

Absorption: Heat generated by the electronic component flows into the heat sink base via direct contact (ideally enhanced with thermal paste or pad).

-

Conduction: This type of heat energy travels through the solid material of the heat sink itself, moving from the hot base outward.

-

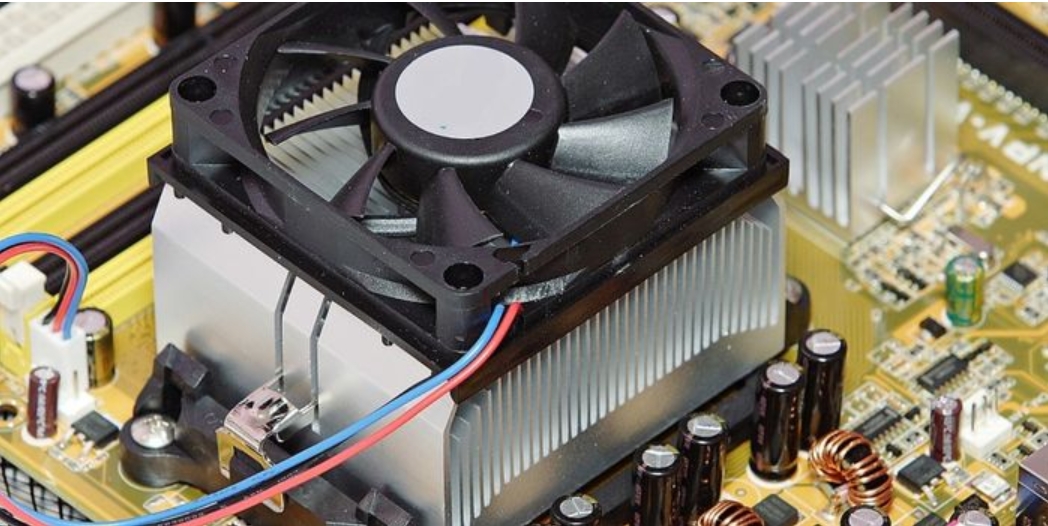

Convection: The heat finally transfers from the heat sink’s large surface area (fins) to the surrounding air. Airflow (natural or forced by a fan) carries the hot air away, cooling the fins so they can absorb more heat.

The efficiency of this process hinges heavily on the heat sink’s design and the material it’s made from.

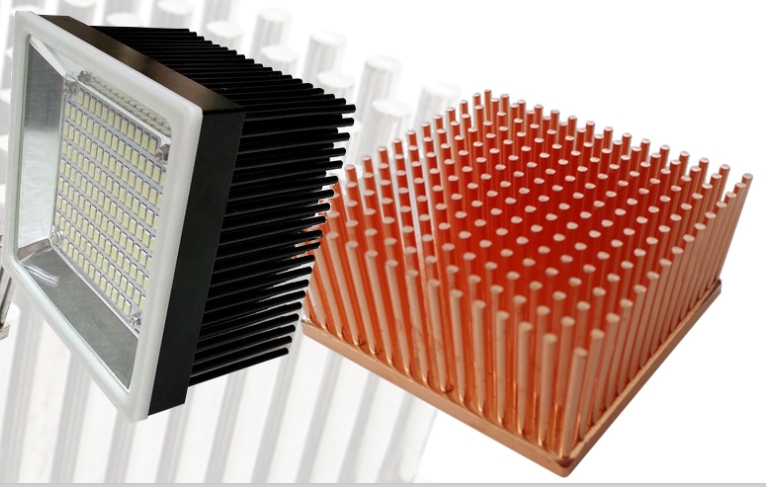

2. Heat Sink Materials: The Copper vs. Aluminum Showdown

-

Aluminum:

-

Pros: Lightweight, relatively inexpensive, easy to extrude into complex fin shapes, good thermal conductivity (~205-230 W/m·K), naturally corrosion-resistant.

-

Cons: Lower thermal conductivity than copper, softer material.

-

Best For: Consumer electronics (laptops, game consoles, LED lights), cost-sensitive applications, applications where weight matters, most extruded heat sinks.

-

-

Copper:

-

Pros: Exceptional thermal conductivity (~385-400 W/m·K), very effective at absorbing and spreading heat quickly from small hotspots.

-

Cons: Significantly heavier, much more expensive, harder to machine or extrude finely, prone to oxidation (tarnishing) without plating.

-

Best For: High-performance computing (servers, overclocked PCs), power electronics, high-heat-flux applications, critical spots where maximum heat spreading is needed (often used in base plates combined with aluminum fins).

-

-

The Hybrid Approach: Often, the best solution combines both! A copper base plate efficiently absorbs and spreads heat from the source, while aluminum fins attached to it provide a large, lightweight, cost-effective surface area for convection. This leverages the strengths of each material.

3. What Factors Impact Heat Sink Performance?

Choosing the right material is crucial, but it’s only part of the equation:

-

Thermal Conductivity: How well the material itself transfers heat (Copper > Aluminum).

-

Surface Area: More fins (within reason) = more area for heat dissipation. Fin density, height, and shape matter.

-

Airflow: Stagnant air is a poor coolant. Natural convection works for low-power devices; forced airflow (fans) is essential for high-power applications. The design must facilitate smooth airflow.

-

Thermal Interface Material (TIM): The paste, pad, or liquid metal between the component and heat sink base is critical. Poor contact drastically reduces efficiency.

-

Mounting Pressure: Ensures good contact between component, TIM, and heat sink base.

-

Design & Geometry: Optimizing fin design, base thickness, and overall shape for the specific application and airflow pattern is key.

4. How to Choose the Right Heat Sink Manufacturer in China

China is a global powerhouse in heat sink manufacturing, but navigating the landscape requires diligence:

-

Define Your Needs: Be crystal clear on specs (thermal resistance, dimensions, power dissipation, material), volume, budget, and timeline.

-

Research & Shortlist: Use platforms like Alibaba, Made-in-China, or industry directories. Look for manufacturers specializing in your type of heat sink (extrusion, bonded fin, skived, stamped, CNC machined).

-

Assess Capabilities:

-

Processes: Do they offer the specific techniques you need (extrusion, die-casting, CNC, soldering, bonding)?

-

Materials: Can they source and work with the required grades of Al/Cu and any surface treatments (anodizing, plating, painting)?

-

Quality Systems: Look for ISO 9001 certification. Ask about their QC processes (incoming material check, in-process inspection, final testing).

-

Engineering Support: Can they help with design optimization or thermal simulation?

-

Prototyping: Do they offer fast, cost-effective prototype services?

-

Minimum Order Quantities (MOQs): Are they feasible for your project? KEVORAPID provide no MOQ.

-

-

Request Quotes & Samples: Get detailed quotes from several shortlisted suppliers. Order prototypes to rigorously test performance and quality.

-

Verify & Communicate: Check references if possible. Ensure clear communication channels. Be explicit about expectations and requirements. Discuss logistics and incoterms.

-

Visit (If Possible): A factory audit provides invaluable insight into operations, capacity, and quality control firsthand.

5. Why Choose Chinese Heat Sink Manufacturers and Suppliers?

The reasons are compelling:

-

Unmatched Scale & Capacity: China boasts immense manufacturing infrastructure capable of handling orders from tiny prototypes to massive production runs.

-

Cost-Effectiveness: Significant economies of scale, competitive labor costs, and mature supply chains lead to highly competitive pricing, especially for aluminum extrusions.

-

Technical Expertise & Variety: Decades of experience have fostered deep expertise across all heat sink manufacturing processes (extrusion, die-casting, bonding, skiving, CNC). You’ll find specialists for virtually any type.

-

Complete Supply Chain: Everything from raw material suppliers (aluminum billets, copper sheets) to surface treatment specialists and logistics providers is concentrated, streamlining production.

-

Rapid Prototyping & Production: Many suppliers excel at fast turnaround times for both prototypes and volume production.

-

Advanced Capabilities: Leading Chinese manufacturers invest heavily in modern machinery, automation, and quality control systems.

6. Conclusion

The choice between copper and aluminum heat sinks involves a careful balance of thermal performance, cost, weight, and manufacturability. Aluminum reigns supreme in cost-sensitive, weight-conscious, and high-volume consumer applications. Copper offers the ultimate thermal conductivity for the most demanding hotspots, often used in hybrids. Understanding the factors affecting performance is key to selecting the right solution.

For sourcing, China presents a formidable option due to its scale, expertise, cost advantages, and comprehensive supply chain. By carefully selecting a reputable manufacturer based on clear criteria and due diligence, you can leverage these benefits effectively to secure high-quality thermal solutions that keep your electronics running cool and reliably.

7. Frequently Asked Questions (FAQ)

-

Q: Is copper always better than aluminum for heat sinks?

-

A: Not necessarily. While copper conducts heat better, aluminum’s lower cost, lighter weight, and ease of manufacturing make it ideal for many applications. Hybrid solutions often offer the best balance. The “best” material depends entirely on the specific requirements (power, space, cost, weight).

-

-

Q: Do copper heat sinks require special maintenance?

-

A: Bare copper will oxidize (tarnish) over time, which can slightly reduce its efficiency and aesthetics. Many copper heat sinks are nickel-plated to prevent oxidation and maintain performance/looks. No routine “maintenance” is typically needed beyond keeping dust clear.

-

-

Q: Can I use a heat sink without a fan?

-

A: Yes, for low-power applications! This is called passive cooling and relies solely on natural convection. Heat sinks designed for passive cooling usually have larger, more widely spaced fins to maximize airflow without forced movement. High-power devices almost always require a fan (active cooling).

-

-

Q: How important is thermal paste?

-

A: Extremely important! Even the best heat sink is ineffective without good thermal contact. Thermal paste fills microscopic air gaps between the component and heat sink base, significantly improving heat transfer. Applying the right amount correctly is crucial.

-

-

Q: What are the main risks when sourcing heat sinks from China?

-

A: Key risks include inconsistent quality (mitigated by strict QC, audits, samples), communication/language barriers, intellectual property protection (use NDAs), logistics complexity, and potential delays. Thorough vetting, clear contracts, and building relationships mitigate these risks effectively.

-