In our hyper-connected world, where devices constantly communicate and power flows invisibly, electrical connectors are the indispensable, often overlooked, workhorses. These critical components form the vital bridges enabling the reliable transfer of electrical power and signals between circuits, devices, and systems. From the smartphone in your pocket to massive industrial machinery and renewable energy farms, connectors ensure seamless operation. Let’s delve into the world of connector manufacturing: their types, materials, how they’re made, and where they power our lives.

What Exactly is an Electrical Connector?

An electrical connector is an electromechanical device designed to create a removable (and sometimes environmental-sealing) interface between different parts of an electrical circuit. They consist of two primary parts: a plug (male connector) and a socket or jack (female connector). When mated, their contacts touch, establishing a continuous electrical path. Key functions include:

-

Connect/Disconnect: Allowing for assembly, maintenance, and component replacement.

-

Power Transmission: Carrying electrical current to devices and systems.

-

Signal Transmission: Relaying data and control signals accurately.

-

Environmental Protection: Shielding contacts from dust, moisture, vibration, and chemicals.

Five Key Types of Electrical Connectors:

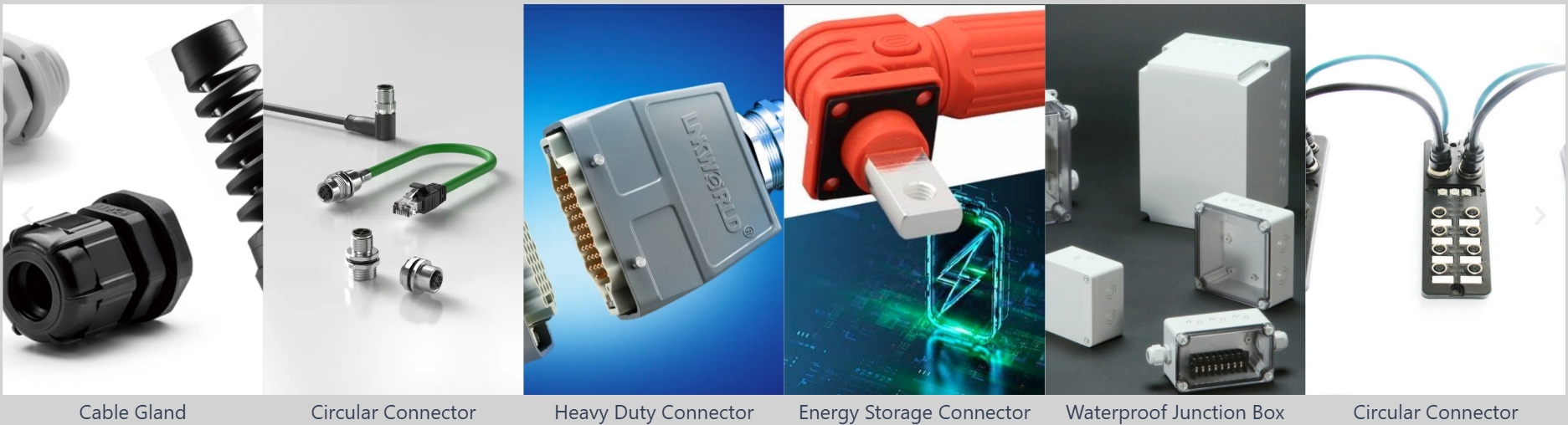

The diversity of applications demands specialized connector designs:

-

Circular Connectors: Characterized by their cylindrical shape and multi-pin configuration. They often feature threaded coupling for secure mating and environmental seals (IP ratings). Ubiquitous in aerospace, military, industrial automation, medical devices, and audio/video equipment due to their robustness, reliability in harsh conditions, and ability to handle multiple signal and power types in one shell.

-

Heavy-Duty (HD) Connectors: Engineered for extreme industrial environments. They boast high current-carrying capacity, exceptional resistance to mechanical stress (impact, vibration), superior ingress protection (IP66/IP67/IP69K), and resistance to oils, chemicals, and UV radiation. Common in factory automation, heavy machinery, construction equipment, and transportation.

-

Cable Glands (Cord Grips): While not connectors themselves, cable glands are crucial sealing components used with connectors and cable entries. They secure and provide strain relief for cables entering enclosures (like junction boxes or control panels) and ensure a high degree of environmental protection (IP rating) by sealing around the cable. Essential for any application requiring sealed enclosures.

-

Waterproof Enclosures & Junction Boxes with Connectors: These housings protect electrical connections and components from water, dust, and corrosion. They incorporate pre-molded entries for cable glands or integrated connectors, providing a complete sealed solution. Vital for outdoor lighting, marine applications, renewable energy installations (solar inverters), irrigation systems, and any exposed electrical connection.

-

Energy Storage Connectors: A rapidly growing category specifically designed for high-voltage, high-current applications in Battery Energy Storage Systems (BESS) and Electric Vehicles (EVs). They prioritize safety (arc prevention, touch-proof designs), handle very high continuous currents and peak surges, manage thermal loads effectively, and ensure reliable connections in demanding environments. Critical for the renewable energy transition and EV infrastructure.

Materials: Building Blocks of Reliability

Connector performance hinges on material selection:

-

Contact Materials: Must conduct electricity efficiently and resist corrosion/wear. Common choices:

-

Copper Alloys: Brass, Phosphor Bronze, Beryllium Copper (high spring strength). Often plated.

-

Contact Platings: Crucial for enhancing performance. Gold (excellent conductivity, corrosion resistance – for signals), Silver (high conductivity, tarnishes – for power), Tin (cost-effective, solderable), Nickel (undercoat, barrier layer, wear resistance).

-

-

Insulator/Housing Materials: Provide electrical isolation, structural support, and environmental protection:

-

Thermoplastics: Polyamide (Nylon – tough, cost-effective), Polybutylene Terephthalate (PBT – heat/stability, chemical resistance), Polycarbonate (PC – impact resistance, clarity), Liquid Crystal Polymer (LCP – high temp, dimensional stability).

-

Thermosets: Rubber (EPDM, Silicone – excellent seals, flexibility).

-

-

Seals & Gaskets: Typically elastomers like Silicone, EPDM, or Nitrile (NBR) chosen for temperature range, chemical resistance, and compression set.

Manufacturing Methods: Precision and Scale

Connector manufacturing blends high-precision machining with efficient molding processes:

-

Stamping & Forming: High-speed presses stamp contact pins and sockets from metal strips, followed by forming into their final shapes. Efficient for high-volume production.

-

Machining (CNC): Used for complex contact geometries, connector shells (especially metal circular types), and prototypes requiring high precision.

-

Molding (Injection & Insert): The primary method for creating plastic housings and insulators. Insert molding places stamped metal contacts directly into the mold cavity, where molten plastic flows around them, creating a strong, integrated component. Essential for complex geometries and sealing features.

-

Plating: Critical finishing step. Contacts undergo electroplating (e.g., gold over nickel) to enhance conductivity, corrosion resistance, solderability, and durability. Processes like reel-to-reel plating automate this for stamped contacts.

-

Assembly: Automated or manual processes assemble stamped/machined contacts into housings, add seals/gaskets, and assemble plug/socket halves. Crimping, soldering, or screw terminals attach wires.

-

Testing: Rigorous quality control includes electrical continuity/insulation resistance checks, mating/unmating force tests, HiPot (dielectric withstand) testing, and environmental testing (IP rating validation, thermal cycling, salt spray).

Applications Across Industries:

Connectors are fundamental to virtually every sector:

-

Automotive & Transportation: Engine control units, sensors, lighting, infotainment, EV batteries & charging systems.

-

Industrial Automation: Robotics, motor controls, PLCs, sensors, machinery power & data.

-

Consumer Electronics: Smartphones, laptops, appliances, charging cables.

-

Telecommunications & Data Centers: Network equipment, servers, fiber optic terminations.

-

Medical Devices: Patient monitors, imaging equipment, surgical tools (requiring high reliability and sterilization compatibility).

-

Aerospace & Defense: Avionics, flight controls, communications, harsh environment reliability.

-

Energy: Power generation/distribution equipment, solar/wind farm connections, BESS.

-

Marine: Navigation systems, lighting, engine controls (saltwater corrosion resistance critical).

Conclusion

Electrical connectors, far from being simple plugs and sockets, are sophisticated products resulting from advanced materials science and precision engineering. Understanding the different types – from robust circular and heavy-duty connectors to specialized cable glands, waterproof enclosures, and high-power energy storage connectors – reveals their tailored roles. The careful selection of conductive and insulating materials, combined with high-precision manufacturing processes like stamping, molding, plating, and rigorous testing, ensures they meet the demanding requirements of reliability, safety, and performance across countless industries. As technology evolves, pushing boundaries in power density, data speed, and environmental extremes, connector manufacturing will continue to innovate, silently powering the connections that drive our world forward.

Frequently Asked Questions (FAQs)

-

What’s the difference between a connector and a terminal? A terminal is the endpoint of a wire (e.g., a spade terminal, ring terminal) designed to attach to a single point (like a screw post). A connector houses multiple terminals (contacts) and provides a mechanism to mate/unmate an entire set of connections simultaneously.

-

What does IP rating mean? Ingress Protection (IP) rating (e.g., IP67, IP68) defines a connector’s or enclosure’s level of protection against solid objects (first digit – dust) and liquids (second digit – water). Higher numbers indicate greater protection.

-

Why is gold plating used on contacts? Gold offers exceptional corrosion resistance and stable, low electrical resistance over time, even for low-voltage signals and frequent mating cycles. It prevents the formation of insulating oxide layers common on other metals.

-

How do I choose the right connector? Consider: Current/Voltage requirements, Signal type (data speed?), Environmental conditions (temp, moisture, chemicals, vibration), Mating cycles required, Size/space constraints, Industry standards, and Cost.

-

What are the trends in connector manufacturing? Key trends include miniaturization, higher data rates (supporting USB4, HDMI 2.1, etc.), higher power density (for EVs/BESS), increased automation in assembly/test, sustainable materials, and enhanced sealing for harsh environments.