Finishing Services

Kevo offers customizable finishing services to match your product design requirements.

Our Post Finishing Services

Surface finishing encompasses various methods used to modify the exterior of a fabricated item to achieve a specific or desired appearance and texture. Various strategies are employed to enhance the aesthetic appeal, adhesion, solderability, corrosion resistance, hardness, conductivity, among other attributes of industrial parts.

At Kevo Rapid, we provide premium surface finishing services for all parts and components, irrespective of the fabrication technique employed. Our team of specialized professionals exclusively handles finishing tasks, ensuring outstanding work quality on your products. If you seek an impeccable finish for your prototypes or other produced components, connect with our customer service team for a fast and precise estimate.

Part Finishing Service Gallery

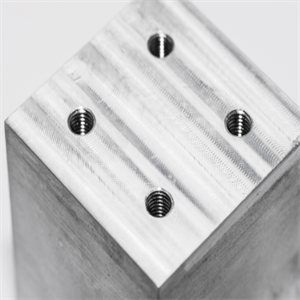

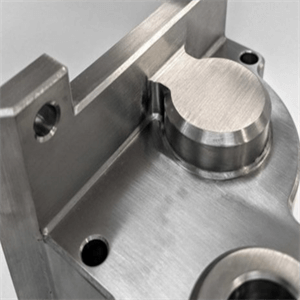

As-Machined

The typical surface texture for our components, referred to “as machined” texture, exhibits a surface roughness of 3.2 μm. This process effectively eliminates sharp edges and ensures the clean removal of burrs from the parts.

Bead Blasting

Bead Blasting is the technique of forcefully propelling, often with increased pressure, a stream of abrasive material against a surface in order to eliminate undesired layers of coating and surface contaminants.

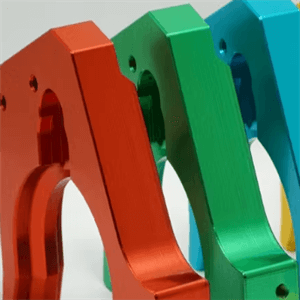

Anodizing

To ensure the durability of our components over time, our anodizing procedure provides excellent protection against corrosion and wear. Additionally, it serves as an optimal surface treatment for painting and priming purposes.

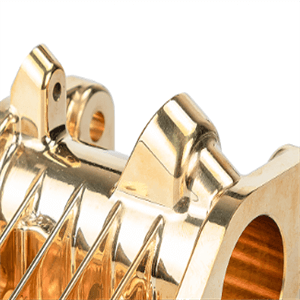

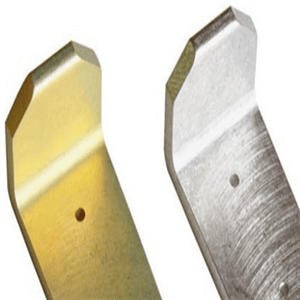

Polishing

With a range between Ra 0.8~Ra0.1, polishing methods employ abrasive materials to gently rub the surface of the component, resulting in a desired level of shine based on your specific preferences and needs.

Powder Coating

By utilizing corona discharge, we effectively facilitate the adhesion of powder coating onto the component, resulting in the formation of a highly durable layer with a typical thickness ranging from 50 μm to 150 μm.

Electroplating

Electroplated coating safeguards the surfaces of components, effectively inhibiting rust formation and preventing other detrimental defects that could lead to deterioration. thereby ensuring long-lasting preservation.

Brushing

Brushing is a surface treatment technique that involves the utilization of abrasive belts to create deliberate patterns or lines on the material’s surface, typically employed for aesthetic enhancements.

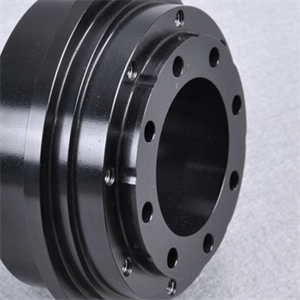

Black Oxide

Black oxide is a conversion coating, akin to Alodine, utilized on steel and stainless steel surfaces. Primarily employed for its visual appeal, it also offers modest protection against corrosion.

Painting

Painting encompasses the process of applying a coat of paint onto the part’s surface using a spray technique. The chosen colors can be precisely matched to a Pantone color code preferred by the customer, while the finishes vary from matte to glossy or even metallic.

Alodine

Chromate conversion coating, often referred to as Alodine, is a chemical treatment that effectively passivates and shields aluminum against corrosion. Additionally, it serves as a foundational layer prior to priming and applying paint onto parts.

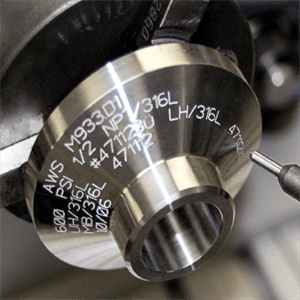

Part Marking

Part marking is an economical method to incorporate logos or personalized lettering into your designs, commonly utilized for bespoke part identification during large-scale manufacturing processes.

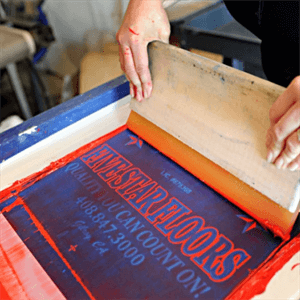

Silk Screen Printing

Silk Screen Printing involves pushing paint through a stencil-covered mesh onto a surface. With precision, it can create complex, multi-colored images and patterns on various flat surfaces. It’s cost-effective, adaptable, and stencils are easily made.