When an industrial designer develops an idea for a new product, prototyping is a critical step in clarifying the functionality

of the product. Prototyping is a process that involves building and testing a physical model of a product design. This article

will guide you through the 7 steps industrial designers follow to create a prototype, and illustrate the many benefits of prototyping.

How to Create a Prototype in 7 Steps

If you want to learn how to create a prototype, you can follow these steps:

1. Conduct Research

When you have a product idea, the first task is to research similar products. Not only will this help you determine if your

idea is innovative, but it will also give you insight into what these products are made of and how they work together to achieve

functionality. This way, you’ll be able to get a clearer picture of product manufacturing and its functionality.

2. Draw a design

Conceptualizing and designing your product is a critical step before embarking on building a prototype. By making sketches,

you can get an initial outline of what the finished product will look like and its potential functionality. Note that these initial

design sketches are only the starting point of your creativity, and it may take a number of revisions and refinements before you

find that design solution that satisfies you the most. Considering that subsequent steps may involve more time and money, it is

often wise to conceptualize and screen out several alternative designs in the early stages, then focus on you think has the most

potential.

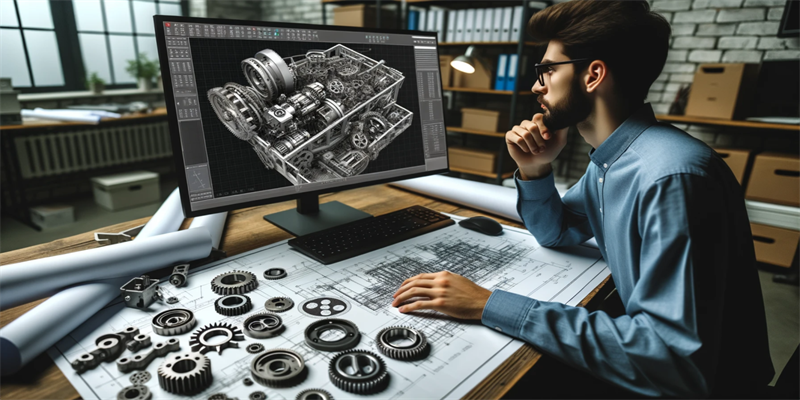

3. Building Virtual Models

Building a virtual model of your product is an important step towards efficient prototyping. During this process, careful consideration

of the materials required for the final product and the potential impact of different forms on the product’s functionality will greatly

facilitate the creation of a model that accurately demonstrates the product’s final appearance and functionality.

4. Evaluate the need for external assistance

Once the product model has been designed, the next step is to evaluate whether you need outside help to create the prototype.

For example, engineers and prototyping experts are both trusted partners. Whichever experts you choose, their involvement will

ensure safe and efficient prototyping. In addition, they can provide valuable advice on design optimization with their in-depth expertise.

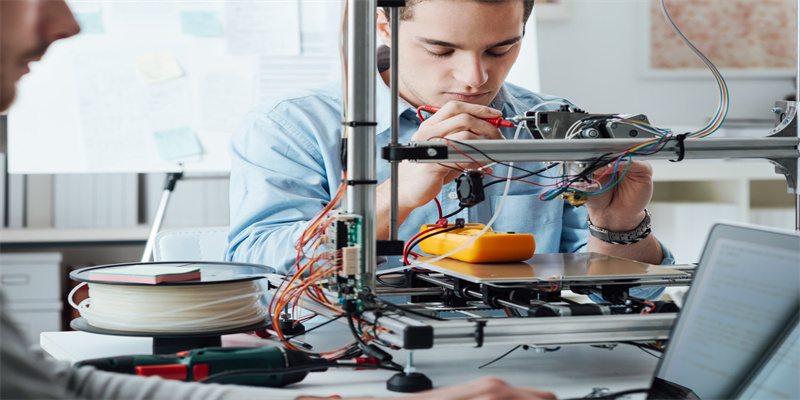

5. Building a Proof-of-Concept Prototype

A proof-of-concept prototype is designed to reveal how a product works. While it may look different from the final product, it is

critical that the prototype incorporates moving or mechanical parts of the design to visually demonstrate how the components

work together. This step is critical to ensure that the product will function as intended.

6. Creating a Functional Prototype

Once you’ve confirmed that the product is functional, the next step is to create a prototype that more closely resembles the model

and design. In the process, you can combine the visual elements of the design with the functionality of the proof of concept. Based

on this information, you’ll be able to determine which parts of the design work and which parts need to be tweaked.

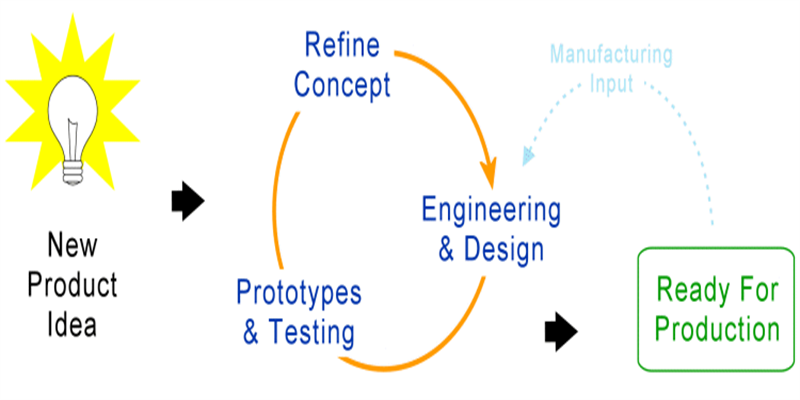

7. Iterative Optimization

After testing the prototype or letting your target users try it out, you may find areas for improvement. At this point, you have

the flexibility to repeat the steps as needed to find the best balance of functionality and design. In the end, you’ll have a perfect

prototype that you’re more comfortable with, whether you’re presenting it to potential investors or going into production.

What are the benefits of using prototypes?

Creating a prototype is an early and crucial part of the product development process to ensure the success of your project, as it

provides you with valuable insight into your product idea. Here are some of the key benefits of using prototypes in the product

design process:

Validate product functionality

By creating a physical model of your idea, you can visually assess whether the product functionality meets expectations. After

testing the prototype, you will be able to judge the usefulness of the product and decide whether you need to invest further time

and resources in optimization.

Reduce Production Costs

It’s often cheaper to create one or two prototypes than to go straight into mass production without testing. Prototypes allow you

to refine the design of your product before investing large amounts of money in production, thus avoiding potential product

defects and recall risks. In addition, prototypes can help you validate the economic viability of your production process and ensure

that you are fully prepared before going into production.

Validate the usefulness of your product

Another effective strategy to improve the efficiency of your product development is to invite some members of your target user

community to try out your prototype. This not only helps you verify whether they find the product practical, but also provides

insights into their preferences and potential room for improvement by collecting their feedback. Based on this valuable input,

you can further optimize your prototype or prepare it for mass production.

Select materials to optimize the product

When you have the initial idea of your product in mind, you probably already have a rough idea of the materials needed and the

final form. With the help of a prototype, you can put these initial ideas into practice and explore ways to build a better quality

product at a lower cost. For example, prototype testing may reveal that the sturdiness and durability of a product can be significantly

improved by tweaking the shape or improving the way parts are connected.

Helping the accuracy of product descriptions

When presenting a industrial product to external partners such as investors, manufacturers, and distributors, they often focus on specific

details such as the size, weight, and portability of the product. A well-developed prototype can provide you with accurate answers

to these key pieces of information, thus helping these outsiders to more fully assess the market potential of the product and decide

whether to invest or assist you in the development of the final product.