Product Prototyping

In the fast-paced business world, companies must respond swiftly to market demand. To maintain competitiveness, it is vital for companies to swiftly create product prototypes, enabling designers and engineers to verify if the design aligns with defined specifications or requirements in the prototype development process. These prototypes serve as a valuable toolbox for ensuring the success of a new product idea in the market.

Create Your Product Prototype

In the fast-paced business world, companies must respond swiftly to market demand. To maintain competitiveness, it is vital for companies to swiftly create product prototypes, enabling designers and engineers to verify if the design aligns with defined specifications or requirements in the prototype development process. These prototypes serve as a valuable toolbox for ensuring the success of a new product idea in the market.

What Type Of Product Prototype Is Needed?

Prototype Iterations in Product Management

- Design Iterations More Flexible

Functional prototype development enables the testing of design iterations and optimization of product performance, leading to the final design. By identifying and addressing any issues early on, this approach minimizes risks to the business plan.

- Move To Full Production With Confidence

Developing a functional prototype simplifies the verification of design, engineering, and manufacturability, thereby reducing the need for costly tools and production investments.

- Cost-Effective Low Volume Manufacturing

Utilizing rapid tooling and custom low-volume production helps bridge the gap between prototyping and production, enabling faster time-to-market for your product at a cost-effective price.

Build Product Prototypes For Your New Product Development

Regardless of the stage of your idea, Our prototype designer has an unmatched ability to quickly create highly accurate, aesthetic, and both functional and manufacturable product prototypes. And validate your prototype design with full prototype testing.

KEVO’s Product Prototyping Capabilities Are Available Throughout Your Development Process

Kevo excels in providing rapid and efficient product prototyping and manufacturing solutions for companies across industries. Specializing in diverse technologies such as CNC machining, 3D printing, vacuum casting, rapid tooling, and low volume injection molding, we ensure a competitive advantage through innovative services and a highly skilled team. With a focus on being your trusted full-service product development partner, we are dedicated to assisting you at every stage of the design process.

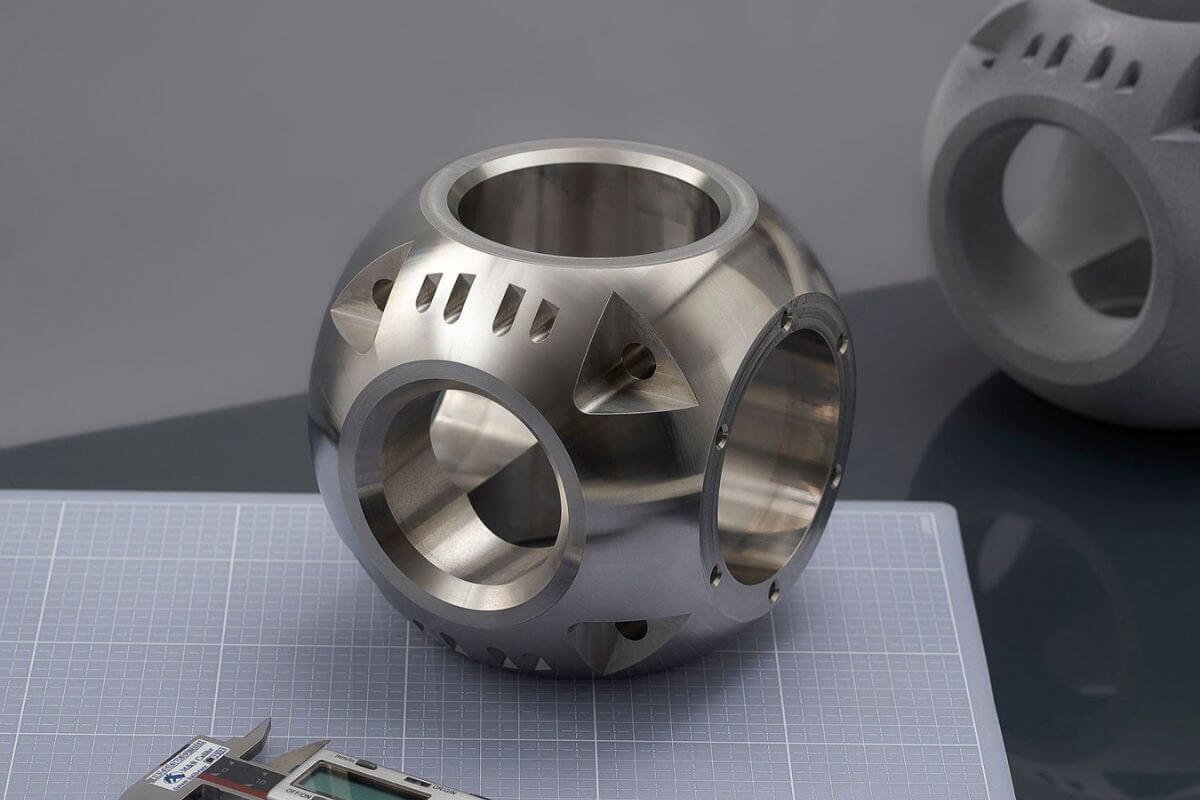

Product Prototypes of Instruments and Equipment

With our extensive experience, we specialize in creating complex working mechanism prototypes that accurately simulate the final product. By employing advanced industrial equipment and multi-part instruments, we ensure precise assembly of components using the same high-quality materials as the end product. Our rigorous testing covers mechanical function, electrical properties, chemical resistance, thermal properties, and product longevity. This allows you to visualize the performance of a part or component in its actual application environment.

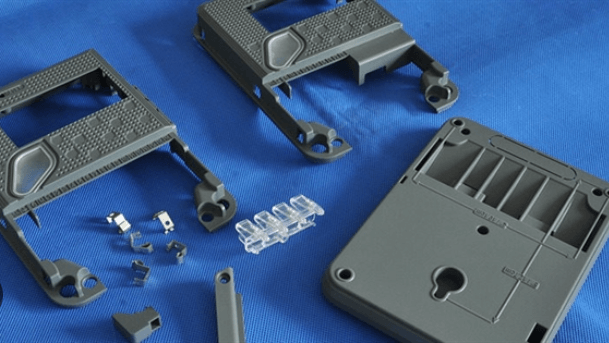

Prototyping for Commercial and Office Products

Kevo excels in product prototyping services designed specifically for manufacturers of commercial and office automation equipment (OA products). Our focus is on developing prototypes that meet exact specifications, faithfully representing vital attributes such as component fit accuracy, dimensional tolerances, and mechanical properties. Leveraging our expertise in high-precision CNC machining, we provide expert advice on material selection, manufacturing processes, and accuracy requirements. This allows us to effectively tackle your engineering challenges and foresee potential production issues.

Prototyping for Commercial and Office Products

For manufacturers of commercial and office automation equipment (OA products), Kevo offers highly suitable product prototyping services. Our focus is on developing prototypes that faithfully capture essential features such as component fit accuracy, dimensional tolerances, and mechanical properties, all while adhering to exact specifications. With our expertise in high-precision CNC machining, we provide expert guidance on material selection, manufacturing processes, and accuracy requirements. This allows us to effectively tackle your engineering challenges and proactively identify potential production problems.