Manufacturing processes have undergone significant advancements in recent years, thanks to breakthrough technologies like the metal sheet process and lithium battery housing. These innovative techniques have revolutionized the manufacturing industry, offering a range of benefits from improved efficiency to enhanced product quality. In this blog post, we will explore the metal sheet process and its applications in creating lithium battery housing, highlighting the advantages and impact on the manufacturing sector.

Understanding the Sheet Metal Process:

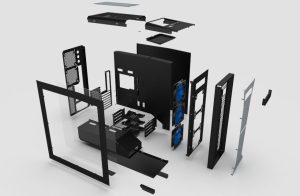

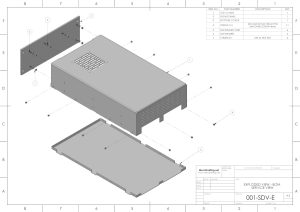

The metal sheet process involves transforming metal sheets into various shapes and sizes to meet specific manufacturing requirements. Specialized machinery, such as laser cutters, CNC machines, and presses, are used to cut, bend, and shape metal sheets according to predetermined specifications.

This process offers numerous advantages over traditional manufacturing methods. Firstly, it enables high precision and accuracy, ensuring consistent product quality. Complex designs and intricate detailing can be achieved, providing manufacturers with the freedom to create innovative and unique products. Additionally, the metal sheet process enhances productivity and efficiency, reducing production time and costs.

Applications of Sheet Metal Processing in Lithium Battery Housing:

One significant application of the metal sheet process is in the creation of lithium battery housing. Lithium batteries are widely used in various industries, including consumer electronics, electric vehicles, and renewable energy storage systems. Metal sheet processing plays a crucial role in manufacturing the housing for these batteries.

The metal sheet process allows for the fabrication of intricate and custom-shaped battery housings. The precise cutting and bending techniques enable the production of lightweight and compact casings, making them ideal for portable electronic devices and electric vehicles. The metal sheet process also ensures structural integrity, protecting the delicate battery components and extending the overall lifespan of the battery.

Advantages of Lithium Battery Housing:

Lithium battery housing offers several advantages, making it an ideal choice for a wide range of applications. Firstly, lithium-based batteries are known for their high energy density, meaning they can store more power in a smaller size. This translates into longer battery life and improved performance for electronic devices and electric vehicles.

Secondly, lithium battery housing provides excellent thermal conductivity, ensuring efficient heat dissipation during operation. This helps prevent overheating, enhancing the safety and longevity of the battery. The metal sheet process allows for the creation of cooling structures within the battery housing, further improving heat management.

Furthermore, lithium battery housing offers superior mechanical strength and durability. Metal sheet processing techniques enable the fabrication of robust and lightweight casings that can withstand various external factors, including impacts and vibrations. This ensures the integrity and safety of the battery, even in demanding environments.

Impact on the Manufacturing Industry:

The integration of the metal sheet process and lithium battery housing has had a profound impact on the manufacturing industry. Manufacturers can streamline their production processes, resulting in increased efficiency and reduced waste. The precise cutting and bending capabilities of the metal sheet process ensure consistent quality, meeting customer expectations and minimizing the risk of product recalls.

Moreover, the use of lithium battery housing has transformed various sectors. In consumer electronics, the lightweight and compact nature of lithium-based batteries has revolutionized the design of smartphones, laptops, and wearables. Electric vehicles benefit from the metal sheet process by enabling the creation of lighter and more aerodynamic battery casings, contributing to improved efficiency and extended range.

Conclusion:

Kevorapid sheet metal process and lithium battery housing have transformed the manufacturing industry, offering numerous advantages in terms of efficiency, product quality, and safety. The ability to shape and customize metal sheets has revolutionized the production of lithium battery housing, enabling the creation of lightweight, durable, and high-performance casings. As technology continues to advance, manufacturers must embrace these innovative techniques to stay ahead of the competition and meet the evolving demands of consumers in sectors such as consumer electronics, electric vehicles, and renewable energy storage.