In today’s world, plastic injection molding has become an indispensable process for manufacturing various products, including cable glands. Cable glands, also known as cable connectors or cable entries, are critical components in electrical systems, ensuring secure and watertight connections for cables passing through enclosures. The plastic injection mold for cable gland production plays a pivotal role in ensuring the quality, durability, and efficiency of these vital components.

Understanding Plastic Injection Molding

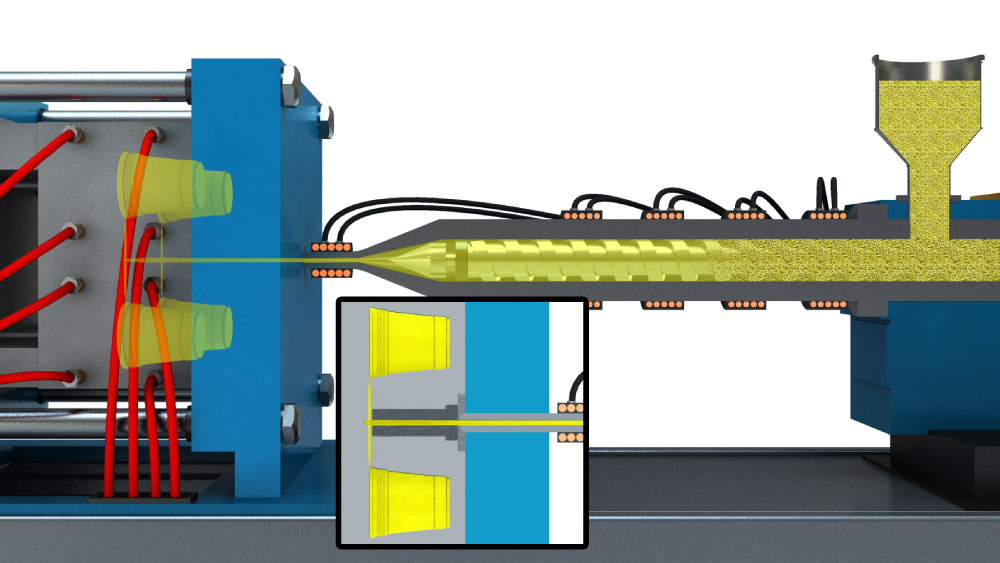

Plastic injection molding is a highly versatile and widely used manufacturing process that transforms plastic raw materials into products of various shapes and sizes. The process involves several key steps, including plasticizing and injection, mold filling, mold opening and stripping, and other auxiliary actions.

-

Plasticizing and Injection: Plastic raw materials undergo preliminary processing, such as drying, screening, and mixing, to become plasticized materials suitable for injection molding. In the heating barrel of the injection machine, the plastic begins to melt and form a uniform molten state. This plasticized plastic is then pushed into the nozzle of the injection machine by the plunger or screw. When the plastic in the nozzle accumulates to a certain amount, the injection machine injects the plastic into the pouring system of the mold, which directs it into the mold cavity.

-

Mold Filling: Under the pressure of the injection machine, the plastic flows through the mold cavity and fills the entire space. During this process, the plastic is subjected to pressure and temperature, which continues to plasticize and melt it. Simultaneously, the cooling system of the mold removes heat from the plastic, allowing it to cool and solidify in the cavity.

-

Mold Opening and Stripping: Once the plastic is cooled and hardened, the mold is opened, and the molded plastic product is pushed out of the mold cavity or removed. This process is called mold opening and stripping. The mold parting surface opens, and the product is ejected or taken out of the mold, ready for further processing or use.

-

Auxiliary Actions: The injection molding process also involves auxiliary actions such as mold exhaust, ejector mechanism adjustment, and mold temperature control. These actions ensure the quality of the product and the stability of the production process.

Plastic Injection Mold for Cable Gland

When it comes to cable gland production, the plastic injection mold is specifically designed to meet the unique requirements of this component. Cable glands must be able to withstand various environmental conditions, including exposure to water, dust, and temperature fluctuations. Therefore, the mold must be precision-engineered to ensure the production of high-quality cable glands with consistent dimensions, tight seals, and excellent durability.

The mold design for cable glands typically includes features such as:

-

Precise Gate Design: The gate, which connects the pouring system to the mold cavity, is crucial in controlling the flow of plastic into the cavity. For cable glands, a well-designed gate ensures that the plastic flows smoothly and uniformly, resulting in a flawless surface finish and dimensional accuracy.

-

Cooling System: An efficient cooling system is essential for rapid and uniform cooling of the plastic in the mold cavity. This helps to minimize warping, distortion, and other defects that can compromise the quality of the cable gland.

-

Ejector System: The ejector system is responsible for pushing the molded cable gland out of the mold cavity. A reliable ejector system ensures that the cable gland is removed without damage, reducing scrap rates and improving production efficiency.

-

Material Selection: The choice of plastic material for cable gland production is also critical. The material must be able to withstand the intended operating conditions, including temperature, pressure, and chemical exposure. Common materials used for cable glands include nylon, PVC, and polypropylene.

Benefits of Plastic Injection Molding for Cable Gland Production

-

Cost-Effectiveness: Plastic injection molding is a highly efficient and cost-effective production method, allowing for the mass production of cable glands at low unit costs.

-

Versatility: The process can be used to produce cable glands in a wide range of sizes, shapes, and materials, meeting the diverse needs of various industries.

-

Precision: The precision of the injection molding process ensures that cable glands are produced with tight tolerances and consistent quality.

-

Durability: The molded plastic cable glands are durable and can withstand harsh operating conditions, making them ideal for use in critical electrical systems.

In conclusion, the plastic injection mold for cable gland production is an essential tool in the manufacturing process. By leveraging the precision, cost-effectiveness, and versatility of plastic injection molding, manufacturers can produce high-quality cable glands that meet the demanding requirements of various industries. With continuous advancements in technology, plastic injection molding is poised to play an even more critical role in the future of cable gland production.